Water Filtration

Water/ Fertilizer systems

The principle of water filtration

Filtration occurs in nature when rain water passes between many layers of sand and gravel. The gravel and sand act as a filter to collect solid particles and therefore leave the water pure. Lubron has adapted this process to achieve the same effect in the agriculture sector. Iron and manganese are often present in natural water sources.

To minimise deposits of these elements and hence make systems more durable, these undesirable substances are filtered out of the water using fully automatic closed and semi-open water filtration systems. We build the next filtration systems:

- Sand filtration ≤ 30 to 40 μm filtration grade.

A sand filter is intended for removing suspended solid particles with a size of approximately 30 to 500 microns from aerobic (oxygen-containing) water.

- Granulate Activate Carbon (GAC):

Activated Carbon is effective for the removal of Chlorine and Organics which can damage and foul Ion Exchange resin and Reverse Osmosis membranes. Activated Carbon has the highest volume of adsorbing porosity, of any material known to mankind. It can be made from a number of substances containing a high carbon content such as coal, coconut shells and wood. Carbon filter systems come in the form of cartridge filters or backwashable filters, both have limited lifespan with the latter lasting the longest before needing to be replaced, because it can be automatically backwashed at timed intervals.

- Activated Filter Media (AFM) ≤ 3 μm filtration grade.

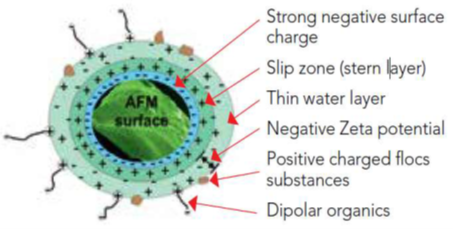

Currently, mainly conventional sand filters are used to filter polluted water. However, sand filters provide a breeding ground for bacteria, causing biofilms to form. A biofilm consists of a layer of microorganisms that produce slime, with which they attach themselves to a surface such as the filter. It is impossible to prevent bacteria from growing on sand, as it is an excellent substrate. Even when a sand filter is continuously rinsed, a very effective biofilm will form on sand. Over time, bacteria form stable channels through a sand filter. Because the polluted process water flows through these channels, it is not filtered, which results in a deterioration of the water quality. AFM is a revolutionary filter medium made of green glass that forms a meso-porous structure (pores with a diameter between 2 and 50 nm) to increase the surface area of the filter. A typical sand filter has a surface area of 3,000 m2 per cubic meter of water while the surface area of an AFM is higher than 1,000,000 m2 per cubic meter of water. This is an increase in surface area of more than 300 times, which means that water is filtered better and faster. Because the glass has negatively charged hydroxyl groups on the surface, this gives the AFM a strong negative charge, also called Zeta potential (see figure). The Zeta potential ensures that insoluble particles – such as (heavy) metals and organic molecules – bind themselves to the glass. In addition, the negative charge prevents colonization of bacteria on the filter, so that no bacteria grow on the filter. Every now and then an AFM must also be rinsed clean to remove the bound substances. However, because the bound substances are retained via a relatively weak electron bond, they are easily rinsed clean and with much less water compared to a sand filter. The big advantage of this is that this AFM filter material no longer needs to be replaced, unlike a sand filter medium.

- Turbidex Filter ≤ 5 μm filtration grade.

Because of the possibility that the well water contains some suspended matter, and/or sand, the well water must first be pre-treated with a high depth bed filter accommodate with specific Turbidex filter material