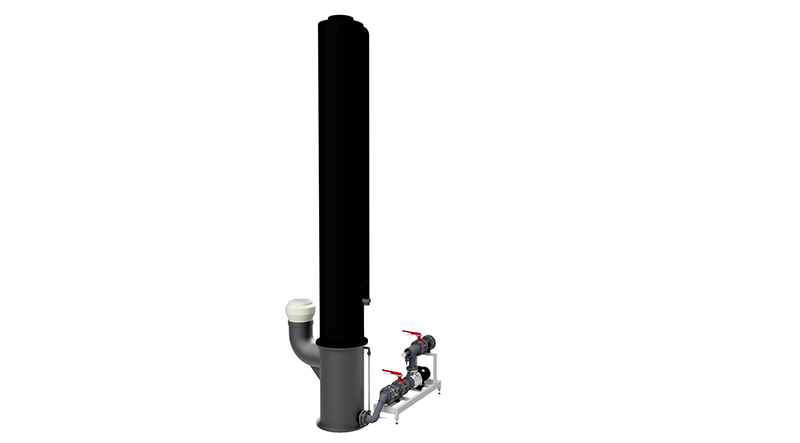

Aeration and degassing tower

Water/ Fertilizer systems

The principle of aeration and degassing tower

To remove undesirable gases, as well as to completely saturate the anaerobe permeate with oxygen. The installation consists of a black polyethylene welded supply tank for the collection of treated water. This supply tank is equipped with a fan with a grid and a cover plate and all necessary connection points for the water intake and outlet of the water to be treated. One black polyethylene aeration and degassing tower, including all necessary components, are installed on the supply tank.

Aeration and degassing is done by means of a noiseless fan. Undesirable gases must be discharged into the outside air. One transport pump placed in a stainless steel frame will transport the treated water to the water supply/storage tank.

The aeration and degassing tower has been developed for enriching source water with oxygen and/or expelling unwanted gases. For example, the permeate produced from spring water by the reverse osmosis plant is generally oxygen-free and in various regions can contain significant amounts of swamp gas/methane (CH4), as well as hydrogen sulfide gas (H2S) and free carbon dioxide (CO2). Although the permeate is bacteriologically and physically pure, it comes into contact with the ambient air and other water types, for example in the basin in which the permeate is often collected. Bacteria may already be present in the ambient air and other types of water, which consume oxygen from the environment during the oxidation of methane gas and can cause explosive growth of often slime-forming biomass. By adequately aerating the permeate with the aeration technique used by Lubron, this slime formation can be kept to a minimum. This aeration technique can also be applied for oxygen enrichment of product water after a reverse osmosis installation, for drain water, as well as for carbon dioxide removal when acid dosing on bicarbonate-containing water is required.

Main benefits of BOT:

- Methane removal: 99.7%

- Maximum oxygen saturation in water, at the relevant temperature;

- Reduction of CO2 and H2S;

The aeration and degassing tower consists of:

A storage tank for collecting the product water, equipped with a fan with grille and cover plate, as well as all necessary connecting pieces for the connection to the water inlet of the water to be treated. An aeration tower is mounted on the storage tank, complete with all necessary parts. The aeration and degassing is done by means of a fan. The height of the tower from the work floor is approximately 5.0 meters. If necessary, this height can be adjusted depending on the measured values of methane and/or other gases. The discharge of unwanted gases must be connected to the outside air at the top (315 mm externally). The buffer is equipped with a pressure transmitter for starting and stopping the supplied pump(s) for transporting the treated water from the BOT, as well as a maximum level alarm contact for stopping the RO installation. The BOT is also equipped with a fan monitor in order to monitor the proper functioning of the BOT and, if necessary, to automatically stop the RO installation if the BOT does not function properly. The aforementioned transport pump will be mounted on a separate frame and controlled from the control cabinet of the RO.